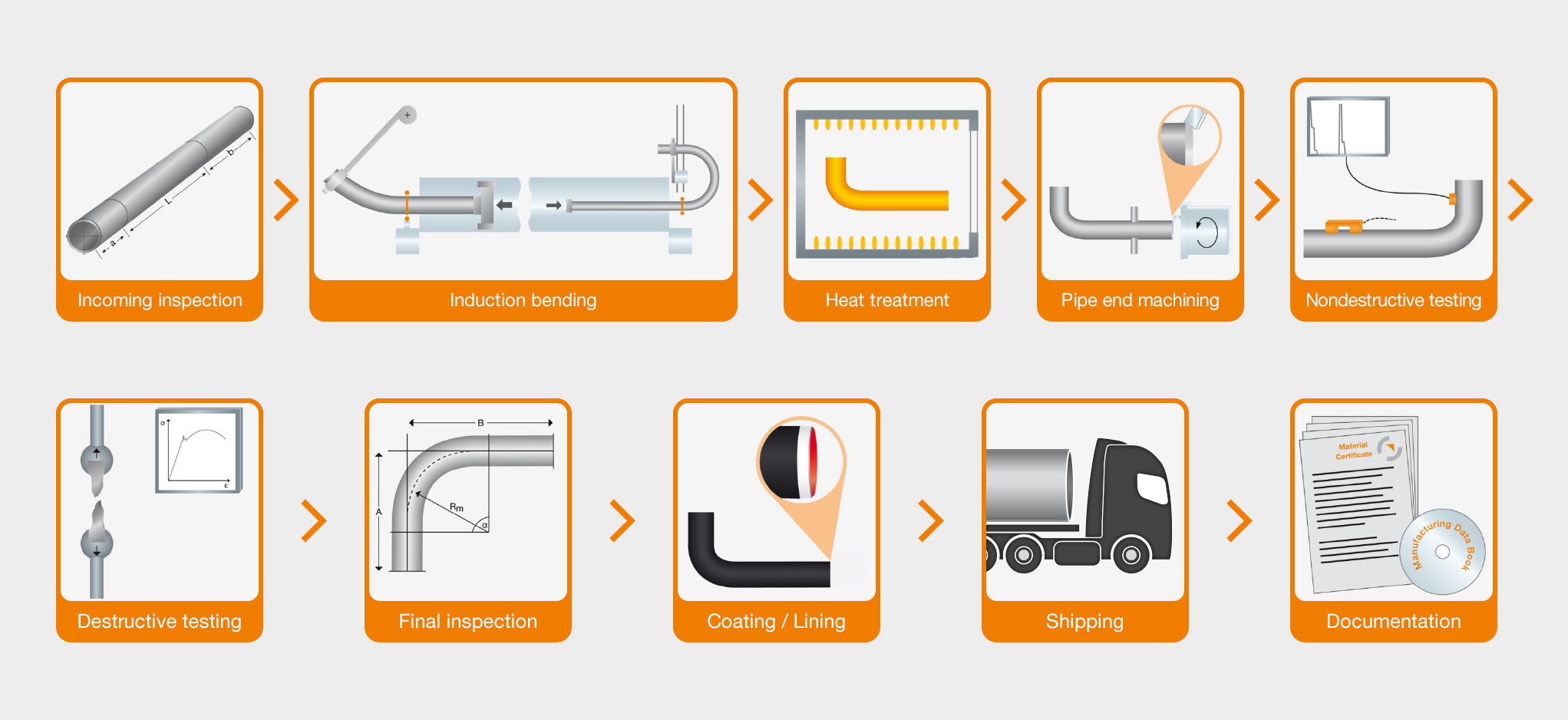

Production process

Our technological lead in the manufacture of induction pipe bends evolved from the ongoing optimization of the complete process chain – from the starting material to the finished product. This is decisively driven by continuously increasing demands in terms of project and customer requirements.

Comprehensive quality assurance measures are embedded into the entire production process. This means we can meet even the most demanding quality requirements. Traceability of all production data based on seamless EDP - from steelmaking to the finished pipe bend – goes without saying.

The essential production steps and quality checks for induction-bent steel pipe are outlined in the following paragraphs. The production path and scope of testing may vary as a function of the customer's specifications regarding the application, material and delivery condition.